Upgrade Your Barn: Rubber Pavers for Safer Equine Facilities

In the quest to enhance the safety and aesthetics of equine facilities, rubber brick pavers for barns are emerging as a transformative solution. Combining durability with elegance, these pavers offer a game-changing alternative to traditional flooring options, making them an increasingly popular choice for horse owners and facility managers. Their impact goes beyond mere appearance; rubber brick pavers provide a non-slip surface that significantly improves the safety for horses and handlers alike, addressing one of the most critical concerns in barn design and maintenance.

This article delves into the myriad benefits of selecting rubber brick pavers for barns, offering a detailed examination of why they stand out as the preferred flooring solution in equine environments. From the installation process to ongoing maintenance and care, readers will gain a comprehensive understanding of how to maximize the advantages of rubber pavers horse barn installations. Additionally, a cost analysis will compare these innovative barn pavers with other materials, offering clear insights into their value proposition. By outlining the key considerations and practical advice for embracing rubber brick pavers, this guide aims to equip barn owners and operators with the knowledge to make informed decisions that enhance the functionality, safety, and aesthetics of their facilities.

Why Choose Rubber Brick Pavers for Barns?

Enhanced Equine Comfort

Rubber brick pavers are renowned for their exceptional comfort, which is crucial for equine health and well-being. These pavers offer significant cushioning compared to traditional concrete or rubber mats. This cushioning effect is not only easier on the joints of horses but also provides anti-fatigue benefits which are essential during long periods of standing, such as grooming or medical examinations. The thickness of the pavers, typically 20mm-30mm, contributes to their ability to absorb impact and reduce the strain on equine legs.

Improved Safety

One of the paramount benefits of rubber brick pavers is their enhanced safety features. The non-slip surface of these pavers drastically reduces the chances of slipping, making them a safer option for areas where horses walk. This is particularly important in environments where water or ice may be present, as the pavers maintain their grip even under these conditions. Additionally, the interlocking design of the pavers ensures a stable walking surface, further preventing accidents. In the unfortunate event of a fall, the soft texture of the rubber significantly lessens the risk of severe injuries

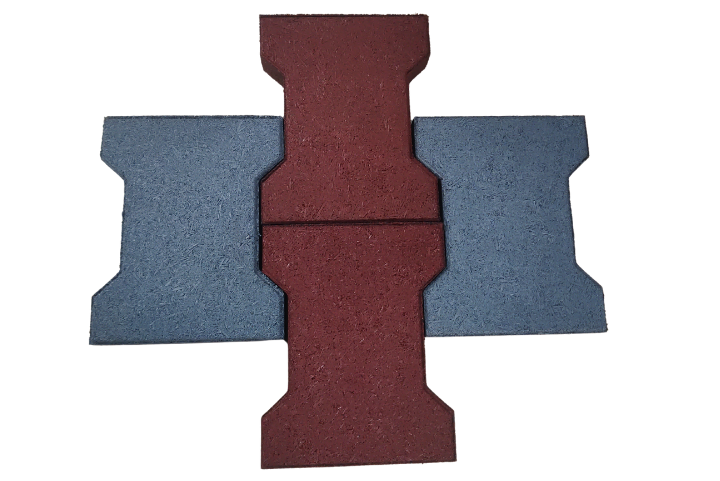

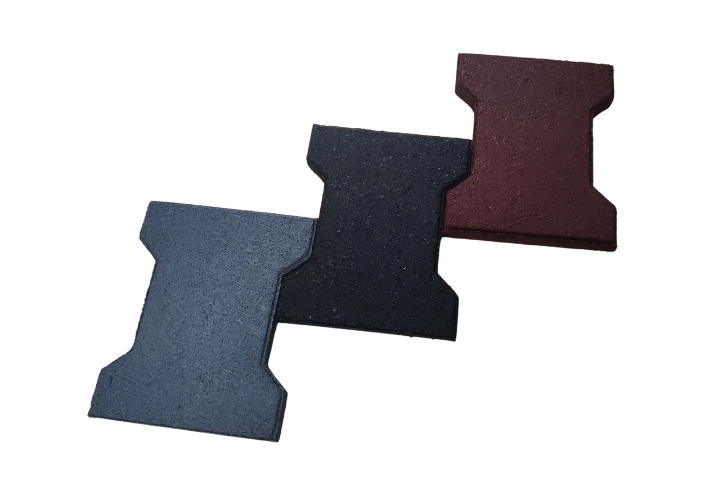

Aesthetic Appeal

Rubber brick pavers not only offer functional advantages but also enhance the aesthetic appeal of barns. They are available in various colors such as black, terra cotta, gray, and forest green, allowing for customization to fit the visual design of any equine facility. The unique “dog bone” shape of the pavers can be arranged in attractive patterns, adding a professional and polished look to barn aisles and stalls. This visual enhancement makes rubber brick pavers an excellent choice for barn owners who prioritize both functionality and style.

By choosing rubber brick pavers for barns, facility managers and horse owners can significantly improve the comfort, safety, and appearance of their equine environments. These benefits make rubber brick pavers a superior flooring solution, aligning with the needs of both horses and their caretakers.

Step-by-Step Guide to Installing Rubber Brick Pavers

Site Preparation

The first crucial step in installing rubber brick pavers is proper site preparation. This involves clearing the area of any debris, ensuring the ground is level, and compacting the soil to provide a stable base. It is essential to remove any organic material like roots or grass, which can decompose and cause uneven surfaces over time. Additionally, a layer of crushed stone should be applied and compacted to enhance drainage and prevent water accumulation under the pavers.

Installation Steps

Laying the Base: After the site is prepared, a layer of fine gravel is spread and compacted to form a smooth, flat surface. This base layer is critical as it supports the pavers and helps to distribute the load evenly.

Setting the Pavers: Begin laying the rubber brick pavers at one corner of the prepared base, pressing them down firmly. It is important to follow a pre-planned pattern to maintain alignment and aesthetic consistency. The unique interlocking design of these pavers aids in their stability and ease of installation.

Cutting Pavers to Fit: In areas where a full paver won’t fit, measure and cut the pavers to size with a utility knife. This step requires precision to ensure that the pavers fit snugly against edges and around obstacles.

Securing the Edges: To prevent the pavers from shifting, secure the edges with a border material, such as aluminum or plastic edging. This border is anchored into the ground and provides a containment that keeps the layout intact.

Post-Installation Checks

Once installation is complete, it’s important to inspect the entire surface to ensure all pavers are level and securely interlocked. Any uneven pavers should be adjusted. To finish, a layer of fine sand can be swept over the surface, filling the gaps between the pavers to help lock them in place and prevent movement.

By following these detailed steps, one ensures that the rubber brick pavers are installed correctly, providing a durable, safe, and aesthetically pleasing surface for equine facilities. This installation not only enhances the functionality of the barn but also contributes to its overall beauty, making it a preferred choice for many facility managers and horse owners.

Maintenance and Care Tips for Rubber Brick Pavers

Routine Cleaning

Rubber brick pavers for barns require only periodic cleaning to maintain their appearance and functionality. Facility managers should employ a water hose with sufficient pressure to wash away dirt and debris caught in the seams and scoring of the pavers. For more thorough cleaning, especially in large barns, using a commercial-grade vacuum, such as an Elgee vacuum, is recommended. This type of vacuum is specifically designed for barn environments, ensuring that hay, manure, and other small particles are effectively removed from the surface and any crevices.

Addressing Wear and Tear

Over time, rubber brick pavers can show signs of wear and tear, such as small cracks or chipping. Regular inspections should be conducted to identify any pavers that require attention. Damaged pavers should be promptly replaced or reset to maintain the integrity and safety of the flooring. If the pavers are installed over a concrete base, it is advisable to incorporate trench or French drains to facilitate adequate drainage and prevent water accumulation, which can exacerbate wear

Preventive Measures

To extend the lifespan of rubber brick pavers, preventive measures should be implemented. Trimming overhanging branches and ensuring proper drainage reduces the amount of organic material falling onto the pavers, thereby minimizing the need for frequent cleaning. For pavers installed over natural substrates like crushed stone or compacted sand, drainage typically occurs naturally from the surface down to the base, aiding in the prevention of moisture-related issues.

Additionally, addressing environmental factors such as oil stains or other stubborn marks is crucial. A mild detergent can be added to the cleaning water to help lift these stains effectively. It is essential to follow up with a thorough rinse using clean water to ensure no residue is left behind, which could attract more dirt.

By adhering to these maintenance and care tips, facility managers and horse owners can ensure that their rubber brick pavers remain a durable, safe, and aesthetically pleasing flooring solution for equine facilities.

Cost Analysis: Rubber Brick Pavers vs. Other Materials

Initial Investment

When considering the initial cost, rubber brick pavers tend to be more expensive than traditional alternatives like concrete pavers or rubber mats. According to industry sources, rubber pavers are the preferred choice for barn aisles due to their durability and safety features, but they come with a higher price tag. Despite that,their superior durability and safety features can lead to significant cost savings over time, making them a valuable investment for your barn.

Long-Term Savings

The long-term benefits of rubber brick pavers can offset the initial investment. Facilities that have installed rubber pavers report no wear even after decades of use, highlighting their durability. Unlike concrete or traditional bricks, rubber pavers do not become slippery, reducing the risk of accidents and associated costs from injuries. Furthermore, the ease of maintenance, such as the ability to clean with simple methods like vacuuming or using a leaf blower, contributes to lower upkeep costs over time.

Cost-Benefit Analysis

A comprehensive cost-benefit analysis reveals that while the initial cost of rubber brick pavers is higher, the long-term advantages make them a financially viable option. Rubber pavers provide a safe and comfortable environment for horses, which is crucial for professional equine facilities prioritizing animal welfare and handler safety 78. The reduction in injury risk and minimal maintenance requirements contribute to overall cost savings, making rubber brick pavers a worthwhile investment for high-quality barn flooring. Additionally, the aesthetic appeal and customization options of rubber pavers enhance the property’s value, further justifying the initial expenditure.

Conclusion

Through our comprehensive exploration of the myriad benefits and practical applications of rubber brick pavers for barns, it becomes evident that Supersafe Industries’ products stand at the forefront of providing safe, durable, and aesthetically pleasing solutions for equine facilities. Rubber brick pavers, with their unique blend of comfort, safety, and visual appeal, have emerged as a superior choice for enhancing the well-being of horses while simultaneously elevating the appearance of barns. The detailed analysis of installation processes, maintenance considerations, and cost-benefit evaluations reinforces the notion that investing in high-quality rubber brick pavers is a strategic decision that yields long-term rewards in terms of both functionality and style.

As we conclude, the significance of selecting the right flooring solution cannot be overstated for those aiming to create safer, more comfortable, and visually appealing equine environments. The introduction of rubber brick pavers into the market by Supersafe Industries marks a significant advancement in barn flooring options, offering an unmatched level of quality and reliability. For facility managers and horse owners contemplating an upgrade to their barns, the decision to invest in rubber brick pavers is validated by their numerous benefits and the positive impact they have on equine health and facility aesthetics. Explore the wide range of rubber brick pavers, including the innovative dog-bone dual-sided paver, at Supersafe Industries, and take the first step towards transforming your equine facility into a safer, more welcoming space for both horses and humans alike.

FAQ

What is the expected lifespan of rubber pavers?

Rubber pavers are a cost-effective choice in the long term due to their minimal maintenance requirements and durability. They are designed to last for more than 20 years, providing a stable and enduring surface.

What is the most economical method for constructing a horse stable?

Using pressure-treated wooden siding is the most budget-friendly option for building a horse stable. While many barns use metal siding, wooden siding is less expensive and offers a natural, rustic look that can complement your surroundings.

Is it possible to install rubber pavers directly on soil?

Yes, rubber pavers can be laid directly on grass or dirt. They are easy to install and can be used to create pathways across any property, including outdoor living areas. This makes them a versatile choice for both outdoor and indoor settings.

How should rubber pavers be installed over concrete?

Before installing rubber pavers on concrete, ensure that the concrete has been fully cured for at least 28 days and is free from hydrostatic pressure. The surface should be flat, level, clean, and dry. Use Polyurethane Adhesive to secure the pavers in place.