EPDM vs. Other Running Track Materials - Why EPDM Reigns Supreme

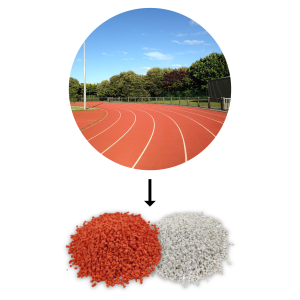

When it comes to choosing a material for your running track surface, there are several options available. However, none can match the superior qualities of EPDM. EPDM, or ethylene propylene diene monomer, is a synthetic rubber material that has been used in a variety of applications for decades. It is an ideal choice for running tracks because of its durability, slip-resistance, and low maintenance requirements. In this blog, we’ll explore the advantages of EPDM compared to other running track materials.

DURABILITY

EPDM is one of the most durable materials available for running track surfaces. It is resistant to weathering, UV radiation, and temperature extremes, making it ideal for use in outdoor environments. It is also resistant to cracking, tearing, and other forms of damage, which means that it can withstand heavy foot traffic and the weight of equipment used for track and field events.

In contrast, other materials like asphalt and concrete can crack and break over time, especially in areas with extreme weather conditions. These materials may require frequent repairs, which can be costly and disruptive.

SLIP-RESISTANCE

Safety is a top priority for any running track, and EPDM excels in this area. Its textured surface provides excellent slip-resistance, even in wet or slippery conditions. This is crucial for preventing slips, trips, and falls, especially during high-speed or high-intensity events.

In comparison, concrete and asphalt surfaces can become slick and hazardous when wet, increasing the risk of injury. Other synthetic materials like PVC and polyurethane may also be slippery and require additional coatings or treatments to improve their slip-resistance.

LOW MAINTENANCE

Maintaining a running track is essential for preserving its performance and longevity. However, the amount of maintenance required can vary depending on the material used. EPDM requires minimal maintenance, making it an attractive option for facilities looking to minimize upkeep costs and downtime.

EPDM is resistant to water, oils, and chemicals, which means that it can be easily cleaned with soap and water. It does not require frequent sealing, recoating, or resurfacing like other materials. In contrast, concrete and asphalt surfaces may require regular sealing and repairs to maintain their integrity.

CUSTOMIZATION OPTIONS

EPDM is available in a wide range of colors, patterns, and designs, which means that it can be customized to match the aesthetics of your facility. This can create a unique and attractive environment for athletes and spectators alike.

In comparison, other materials like concrete and asphalt are limited in terms of customization options. While synthetic materials like PVC and polyurethane offer some degree of customization, they may not be as durable or slip-resistant as EPDM.

In conclusion, EPDM is the superior choice for running track surfaces. Its durability, slip-resistance, low maintenance requirements, and customization options make it a top-performing and cost-effective option for any facility. Whether you’re building a new track or replacing an old surface, consider EPDM for the best results.